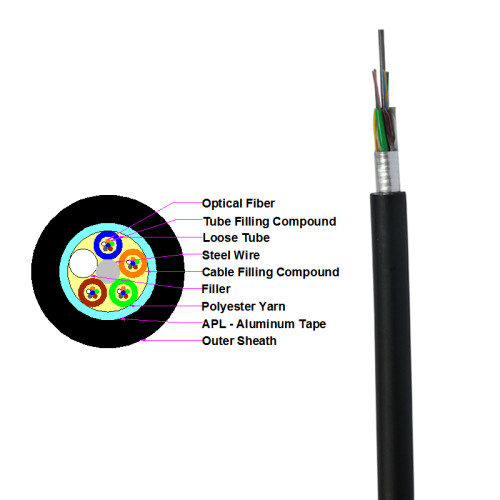

SM Stranded Loose Tube metallic Strength Member Armored Cable

- 型号

- GYTS

属性

- Fiber Count

- 2~144 cores

- Fiber Type

- G652D; G657A

- Strength Member

- Steel wire

- Filler

- PP

- Water blocking material

- Water Block Tape/ Jelly

- Loose tube

- PBT(2.0mm-3.5mm)

- Outher sheath

- Ploythene (PE) Jacket

- Package

- 2 kilometer per drum

- Application

- Aerial / Duct

- Armored material

- Corrugated Steel Tape

评价

产品描述

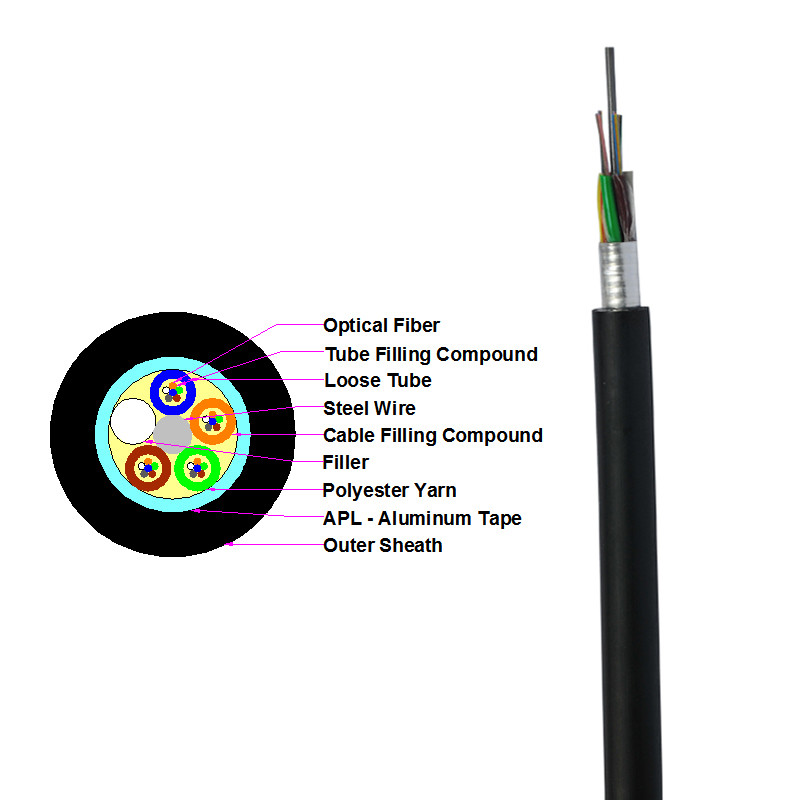

1.1 General Design(metallic Strength Member Armored Cable)

OpticalFiber is constructed of a germanium doped silica based core with a pure silicacladding which meets ITU-T G.652 standard. Two layers of UV curable acrylateprotective coating are applied over the cladding to provide maximum fiberlifetime.

1.2 G.652.D fiber

1) Construction | |

|---|---|

Mode Field Diameter @ 1310 nm | 9.2 +/-0.4 µm |

Core-Cladding concentricity error | ≤0.4 µm |

Cladding diameter | 125 +/-1 µm |

Cladding non-circularity | ≤1 % |

Primary coating material | UV curable acrylate |

Primary coating Diameter | 250 +/-15 µm(Colored) |

2) Optical Characteristics | |

Attenuation @ 1310nm | ≤0.36 dB/km |

@ 1383nm | ≤0.35 dB/km |

@ 1550nm | ≤0.22 dB/km |

Dispersion @ 1288~1339nm | ≤3.5 ps/(nm.km) |

@ 1271~1360nm | ≤5.3 ps/(nm.km) |

@ 1550nm | ≤18.0 ps/(nm.km) |

Zero dispersion wavelength | 1300 – 1324 nm |

Zero dispersion slope | ≤ 0.092 ps/nm2×km |

Cabled cut-off wavelength (lcc) | ≤1260 nm |

Polarization Mode Dispersion | ≤0.2 ps/√km |

3) Mechanical Characteristics | |

Proof stress level | 1.2 % (0.86 GPa) |

Fiber curl (Fiber radius of curvature) | ≥4 m |

Macro bending induced attenuation | 100 turns 30 mm radius ≤ 0.1 dB at 1550nm |

4) Refractive index | 1.466 @ 1310nm 1.467 @ 1550nm |

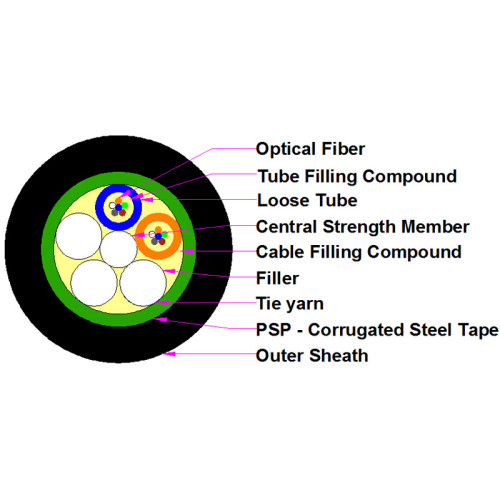

2. Fiber Optic Cable

2.1 GeneralDesign

The colorcoded fibers are housed in multiple color coded plastic loose tubes which arestranded around a central strength member utilizing Reverse Oscillating Lay(ROL).

Waterblocking yarn and water-blocking tape, filling the interstices within the core,provides protection against water ingress.MDPE sheath with 2 rip cords iscovered over the cable core.

2.2 Construction

| Item | Specification |

|---|---|

| Central strength member | FRP OD: 2.0mm(8,12,16,24,36 fibers) 2.3mm(48,72 fibers) 2.5mm(96 fiber) 3.0mm(144 fiber) |

| Loose tube | PBT OD: Nom.2.0mm(8,12,16,24,36 fibers) OD:Nom.2.2mm(48,72,96,144 fibers) Thickness:0.3mm |

| Filler | Plastic OD: 1.95mm(8,12,16,24,36 fibers) 2.15mm(48,72,96,144 fibers) |

| Rip-cord | 3 strands per pcs(Symmetrial distribution in the sheath) |

| Water-blocking tape | 20mm*0.25mm(8,12,16,24,36 fibers) 22mm*0.25mm(48,72 fibers) 28mm*0.25mm(96 fiber) 36mm*0.25mm(144 fiber) |

| Outer sheath | MDPE Thickness:2.0mm |

2.3 Loose Tube Stranding

Fiber count | Max.fiber number per tube | Number of tube / Filler |

|---|---|---|

8/12 | 6 | 2 / 4 |

16 | 6 | 3 / 3 |

24 | 6 | 4 / 2 |

36 | 6 | 6 / 0 |

48 | 12 | 4 / 2 |

72 | 12 | 6 / 0 |

96 | 12 | 8 / 0 |

144 | 12 | 12 / 0 |

2.4 Cable Diameter and Weight

Fiber count | Nom. diameter (mm) | Nom. weight (kg/km) |

|---|---|---|

8/12/16/24/36 | 10.5 | 82 |

48/72 | 11.2 | 94 |

96 | 12.6 | 119 |

144 | 15.4 | 179 |

2.5 Color Coding

Each fiberand tube shall be identifiable throughout the length of the cable in accordancewith the following color sequence. Fibercolor in each tube starts from No. 1 Blue.

Fiber/Tube No | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

Color | Blue | Orange | Green | Brown | Gray | White |

Fiber/Tube No | 7 | 8 | 9 | 10 | 11 | 12 |

Color | Red | Black | Yellow | Red | Pink | Aqua |

2.6 Sheath Marking

The sheathmarking are hot stamped on the sheath at one meter interval with white color. Theaccuracy of the length marking shall be 0 ~ +1%.

Re-markingis yellow color, if necessary.

***: Customer’s name

xxFIBRE: Fiber count

Month/Year:Manufacture date

XXXXM: The figure ofmeter.